Uhlobo lokugcina olubandayo

Ngobushushu:

Ubushushu obuphezulu bogcino olubandayo (±5℃): lulungele ukugcinwa kweziqhamo nemifuno.

Ubushushu obuphakathi (00℃~--5℃): ilungele ukutya okubandayo emva kokunyibilika.

Ubushushu obuphantsi bendawo yokugcina ebandayo – 20 ℃): ilungele imveliso ekhenkcezileyo, ukutya kwenyama yenkukhu – 10 ℃ iimveliso zasemanzini.

23℃ okwethutyana: ilungele ukuhlala kancinci phambi kogcino olubandayo olulandelayo.

Ngomthamo:

Indawo encinci ebandayo:<500m³;

Ugcino oluphakathi olubandayo: 500~1000m³;

Ugcino olukhulu olubandayo: >1000m³;

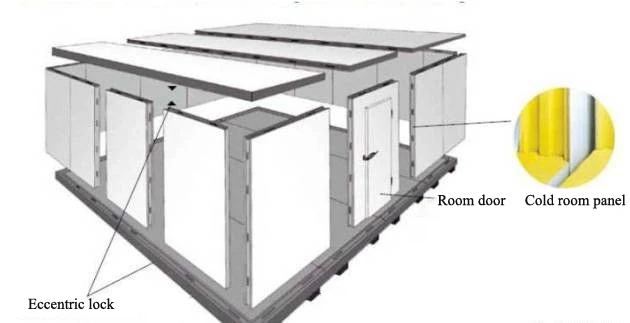

Isakhiwo kunye nezixhobo eziphambili zokugcinwa okubandayo

Iphaneli : Iveliswe kwangaphambili, ngobude obusisigxina, ububanzi kunye nobukhulu, obunokukhethwa ngokweemfuno zokufakelwa kwegumbi elibandayo. Iipleyiti ezinobunzima obuyi-10 cm zisetyenziselwa ukugcina ubushushu obuphezulu naphakathi, kwaye iipleyiti ezinobunzima obuyi-12 cm okanye i-15 cm zisetyenziselwa ukugcina ubushushu obuphantsi kunye nokugcinwa kweqhwa.

Isakhiwo kunye nezixhobo eziphambili zokugcinwa okubandayo

Kwiimeko eziqhelekileyo, iifriji ezincinci zisebenzisa i-compressors ze-hermetic ngokupheleleyo. Izikhenkcezisi ezinobungakanani obuphakathi ngokubanzi zisebenzisa i-semi-hermetic compressors. Iifriji ezinkulu zisebenzisa i-semi-hermetic compressors okanye i-screw compressors. Xa ukhetha, i-compressor yefriji ye-ammonia nayo ingaqwalaselwa, kuba i-ammonia i-compressor yefriji yefriji inamandla amakhulu kwaye ingasetyenziselwa iinjongo ezininzi, kodwa ukufakela kunye nokulawula kunzima kakhulu.

Umphunga:

Kwiimeko eziqhelekileyo, iindawo zokugcina ukushisa okuphezulu zisebenzisa abalandeli njenge-evaporators, ezibonakaliswe ngesantya sokupholisa ngokukhawuleza, kodwa kulula ukubangela ukulahleka komswakama kwiimveliso ezifakwe efrijini; iindawo ezibandayo zobushushu obuphakathi nezisezantsi ikakhulu zisebenzisa imibhobho ephumayo eyenziwe ngemibhobho yentsimbi engenamthungo, ephawulwa ngesiphumo sobushushu obungaguqukiyo bulungile, kwaye inokugcina ukubanda ngexesha.

Icondenser:

I-condenser inomoya wokupholisa, ukupholisa amanzi kunye nomoya kunye namanzi kunye neendlela zokupholisa ezidibeneyo. Ukupholisa umoya kunqunyelwe kwizixhobo ezincinci zokugcina ezibandayo, ngelixa i-condensers epholileyo yamanzi ingasetyenziselwa kuzo zonke iindlela zefriji.

Ivalve yokwandisa:

I-valve yokwandisa i-thermal ihlulwe ibe yi-valve yangaphakathi yokwandisa ibhalansi kunye ne-valve yokwandisa ibhalansi yangaphandle. Uxinzelelo lwe-inlet ye-evaporator luvakalelwa phantsi kwe-diaphragm ye-valve yokwandisa ibhalansi yangaphakathi; ukuvela komphunga kuvakala phantsi kwe-diaphragm yevalve yokwandisa ibhalansi yangaphandle. uxinzelelo lokuphuma.

Isiqokeleli :

gcina iFreon ukuqinisekisa ukuba ifriji isoloko ikwimeko egcweleyo.

Ivalve yeSolenoid:

thintela indawo yoxinzelelo oluphezulu lolwelo lwefriji ekungeneni kwi-evaporator xa icompressor imisiwe, gwema uxinzelelo oluphantsi ekubeni luphakame kakhulu xa icompressor iqalwa kwixesha elizayo, kwaye uthintele icompressor kwishock yolwelo. Ukongezelela, xa iqondo lokushisa elibandayo lifikelela kwixabiso elimiselweyo, i-thermostat iya kwenza, i-valve ye-solenoid iya kulahlekelwa amandla, kwaye i-compressor iya kumisa xa uxinzelelo oluphantsi lufikelela kwixabiso elimiselweyo. Xa umbane uvuliwe, i-compressor iqala xa uxinzelelo oluphantsi lukhuphuka kwi-compressor iqala ukubeka ixabiso.

Umkhuseli woxinzelelo oluphezulu noluphantsi:

khusela i-compressor kuxinzelelo oluphezulu kunye noxinzelelo oluphantsi.

Thermostat:

Ilingana nengqondo yendawo yokugcina ebandayo elawula ukuvulwa kunye nokuvalwa kwefriji, ukuchithwa, kunye nabalandeli bendawo yokugcina ebandayo.

Isihluzi somiso:

filter ukungcola kunye nokufuma kwinkqubo.

Isikhuseli soxinzelelo lwe-oyile:

Qinisekisa ukuba icompressor ineoyile yokuthambisa eyaneleyo.

Isahluli se-oyile:

Umsebenzi walo kukwahlula ioli yokuthambisa kwi-steam ephezulu yoxinzelelo ekhutshwe kwi-compressor yefriji ukuqinisekisa ukusebenza okukhuselekileyo nokusebenzayo kwesixhobo. Ngokomgaqo wokuhlukana kweoli ngokunciphisa isantya sokuhamba komoya kunye nokutshintsha isalathiso sokuhamba komoya, iinqununu zeoli kwi-steam yoxinzelelo oluphezulu ziyahlukana phantsi kwesenzo sobunzima. Ngokuqhelekileyo, xa i-airflow velocity ingaphantsi kwe-1m / s, iinqununu ze-oyile ezinobubanzi obungaphezulu kwe-0.2mm equlethwe kwi-steam inokwahlulwa. Kukho iintlobo ezine zezahluli zeoli ezisetyenziswa ngokuqhelekileyo: uhlobo lokuhlamba, uhlobo lwe-centrifugal, uhlobo lokupakisha kunye nohlobo lokucoca.

Ixesha lokuposa: Nov-14-2022